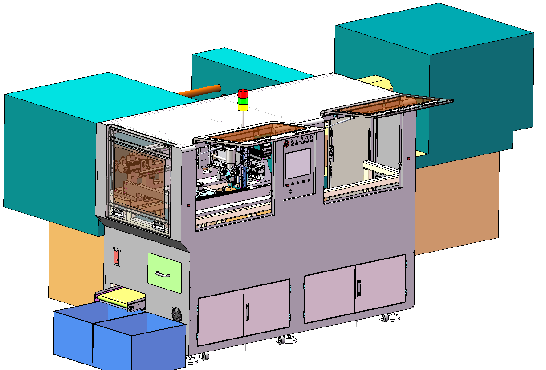

Fully Automatic Pipette Tip Production Equipment (TTR -- TIP TO RACK)

Fully Automatic Pipette Tip Production Equipment (TTR -- TIP TO RACK)

1. Specifications:

· Dimensions: L3.7*W1.5*H2.4m (including 0.5m injection molding machine maintenance channel)

2. Parameters:

· Voltage/current: AC380±10V/50Hz

· Air source: ≥0.6MPA ≥3500L/Min

· Environmental requirements: Noise < 60db

3. Features:

· Small equipment size and high space utilization.

· High stability. The whole equipment adopts high rigid structure to ensure the stability of the equipment.

· High production efficiency, fully meeting the online matching mold opening time of injection molding machine.

· High compatibility, compatible number of holes (full heat/semi-heat) : 16, 32, 48, 64 points.

· Integrated needle detection, filter element implantation and other functions, with high degree of automation.

· Production traceability. The medium plate semi-finished products produced by each machine have traceability code, which can trace the production source.

· No manual participation in the whole process, realizing unmanned chemical plant and saving labor costs.

· Modular design, high flexible production line. Host equipment once input support subsequent expansion, good scalability. (Visual inspection, filter element implantation and packaging are optional)

· Production quality assurance: all needles are tested to ensure quality.