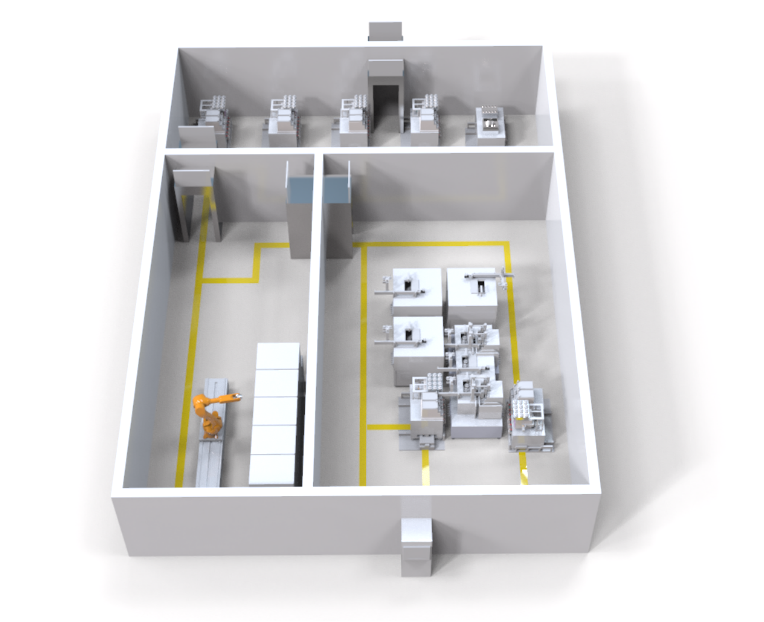

Myocardial Cell Regeneration Production Line

1. Features:

· Process implementation:

(1) Three turnover cars complete the loading and unloading operation of all materials in area B, avoiding the repeated assembly and disassembly of mechanical arms in area A, improving the system reliability and greatly shortening the time.

② The sterilization car can be quickly connected to the interface of all piping systems in the sterilization and cleaning operation of zone A, and can automatically complete the rapid and efficient sterilization of all piping systems in Zone A.

· Time efficiency:

① Multiple cell factories operate synchronously on the turnover trolley, greatly reducing the exposure time of cells in non-culture environment and improving the survival rate of cells.

(2) The cleaning and sterilization time and material preparation time of the system are less than 1/4 of the mechanical arm scheme.

2. Advantages and Highlights:

(1) The preparation time of zone A is only 1/4 of that of the original manipulator scheme. One area A can complete no less than two areas A of the manipulator scheme.

(2) AGV vehicle can not only meet the current planning requirements, but also move to multiple A zones for operation in the future planning.